Process Overview

The processing pathway of our operations commences at our Steelpoortdrift Project with the open pit mining of titaniferous vanadium ore which is then put through an onsite concentrator (using magnetic separation) for its primary treatment, converting the ore to a vanadium rich concentrate. The concentrate from the Steelpoortdrift Project will then be sent to our SRL where it undergoes a treatment to produce a >98% V2O5 flake. The onsite concentrator and SRL plant at the Steelpoortdrift site have both been designed using established technology which is currently in use both within the Bushveld region and internationally.

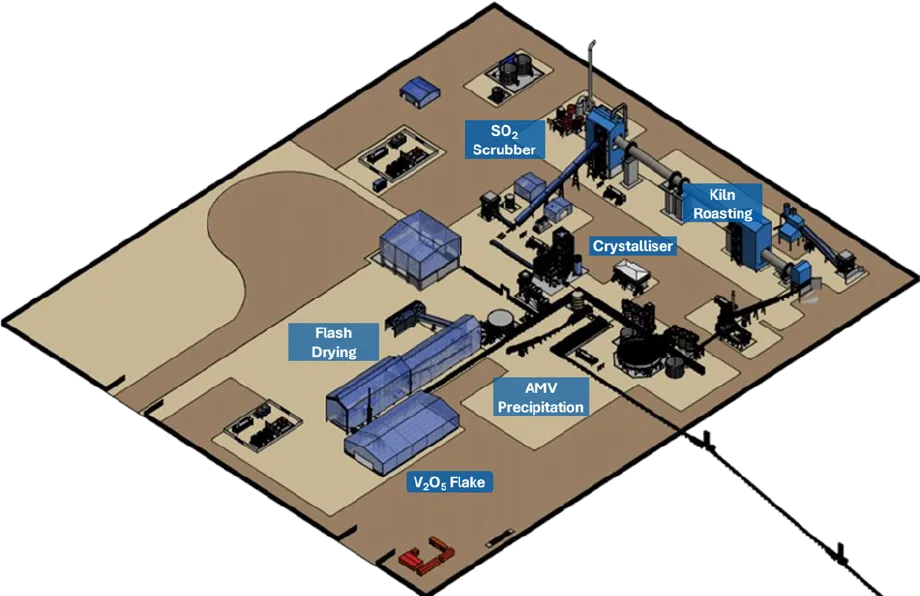

SRL Plant

The SRL plant will receive a vanadium rich concentrate to produce a final product of >98% Vanadium Pentoxide flake (V2O5). The SRL plant comprises several steps including kiln roasting, leaching, desilication, AMV precipitation, flash drying and V2O5 flake production. The designed plant also includes an evaporation and crystallisation component to recover Na2SO4 crystals for recirculation o the kiln. Initially the SRL plant will produce an average of 10,700t of V2O5 flake per annum (capacity of ~12ktpa), once Stage 2 of our operations commences the production rate will increase to an average rate of 21,000t of V2O5 per annum (capacity increases to ~24ktpa).

Figure below: Proposed SRL Plant (according to the 2022 Definitive Feasibility Study). For the latest proposed modifications, refer to ASX Release, 13th September 2024.